Submit Your Request

Please fill out the form below.

Please fill out the form below.

Need a custom solution?

The automotive industry is in a continuous state of evolution, with a growing emphasis on vehicle ergonomics, user experience, and long-term reliability. A key area of innovation is the power seat, a feature that has become a standard of luxury and convenience. However, traditional motorized seats, which have historically relied on brushed DC motors, face significant challenges. These motors are known for their physical brushes, which cause friction, wear out over time, and create acoustic and electrical noise. These drawbacks translate into a less than ideal user experience, higher maintenance requirements, and a shorter operational lifespan, which are unacceptable for today’s high-end vehicles.

Automotive designers and engineers are tasked with a new challenge: to find a motion control solution that can provide the necessary power and precision for seat adjustment while ensuring whisper-quiet operation, superior durability, and a compact form factor. The motor must be capable of handling the high-torque demands of moving a seat, offer precise control for memory functions, and integrate seamlessly into a vehicle’s sensitive electronic ecosystem without generating disruptive noise. The goal is to elevate the user experience, providing a smooth, quiet, and reliable adjustment that enhances the perception of quality and luxury in a modern vehicle.

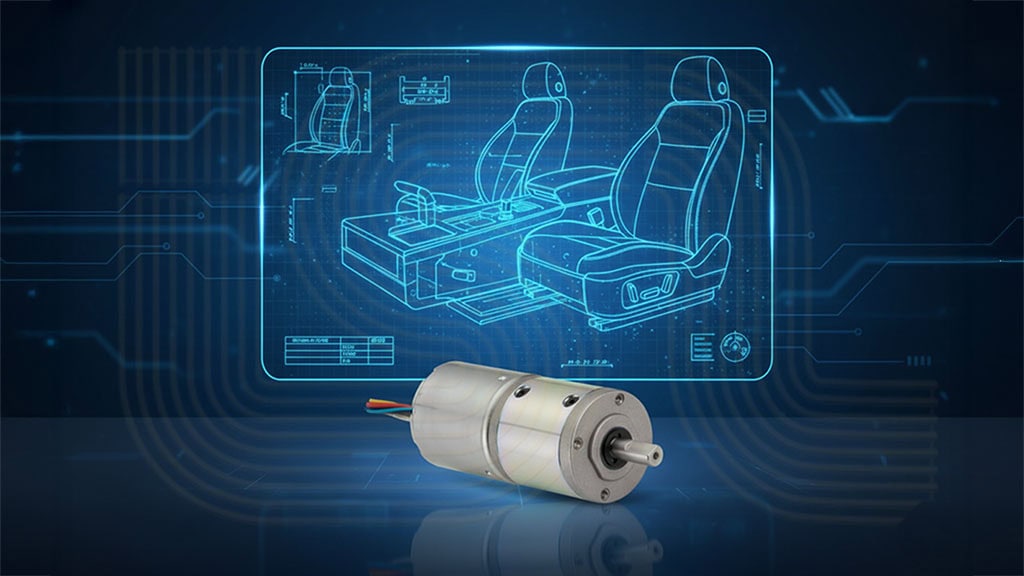

To meet these demanding requirements, ISL Products International identified the PGMBL-42H-24-51-75-66A, a high-quality brushless DC (BLDC) planetary gear motor, as the optimal solution. This component represents a strategic pivot from traditional brushed technology to an advanced system engineered for the specific needs of the automotive industry.

The selection of the PGMBL-42H-24-51-75-66A was based on a comprehensive evaluation of its technical attributes, which directly addressed the core challenges of modern power seat design:

The strategic integration of the PGMBL-42H-24-51-75-66A motor system into the power seat assembly yielded significant positive outcomes, directly addressing the key challenges and elevating the product’s value proposition.

The shift from a brushed to a brushless design had a profound impact on the system’s long-term viability. For an automotive manufacturer, this translates directly into a reduction in warranty claims, a lower total cost of ownership (TCO) over the vehicle’s lifespan, and a more reliable product. The motor’s longevity and robust design make it a strategic investment that provides lasting value well beyond the initial cost.

A primary goal of the design was to improve the in-cabin experience. The BLDC motor’s inherently quiet operation—resulting from the absence of friction and arcing—made a noticeable difference. The smooth, near-silent movement of the seat enhances the perception of a high-quality, meticulously engineered vehicle. This quiet motion control is a critical feature, particularly in electric vehicles, where the lack of engine noise makes every subtle sound more apparent.

The BLDC motor’s superior power-to-weight ratio allowed the manufacturer to design a more compact and streamlined seat mechanism without compromising on performance. This space optimization is invaluable in modern vehicle design, where every millimeter of space is at a premium. The motor’s high torque and precise control also ensured that the seat could move fluidly and accurately, regardless of the user’s weight or the resistance from the mechanism. This performance consistency is vital for user satisfaction and for the reliable function of features like memory seat presets.

The PGMBL-42H-24-51-75-66A gear motor proved to be the ideal solution for this automotive application. Its successful integration demonstrates how a shift to brushless DC technology can solve the inherent limitations of traditional brushed motors, delivering a superior blend of quiet operation, extended lifespan, and reliable performance. This gear motor is not merely a component; it is a critical part of a premium user experience, a critical factor in a highly competitive automotive market.

The success of this case study positions ISL Products International as an expert and forward-thinking partner for the automotive industry. We understand that modern motion control requires more than just a motor—it requires a solution that is durable, efficient, and capable of enhancing the end-user experience.

We invite you to discover how our high-quality brushless DC gear motors and other advanced solutions can help you drive innovation in your next project. Contact us today to discuss your specific requirements and let ISL Products be the driving force behind your success.