Submit Your Request

Please fill out the form below.

Please fill out the form below.

Need a custom solution?

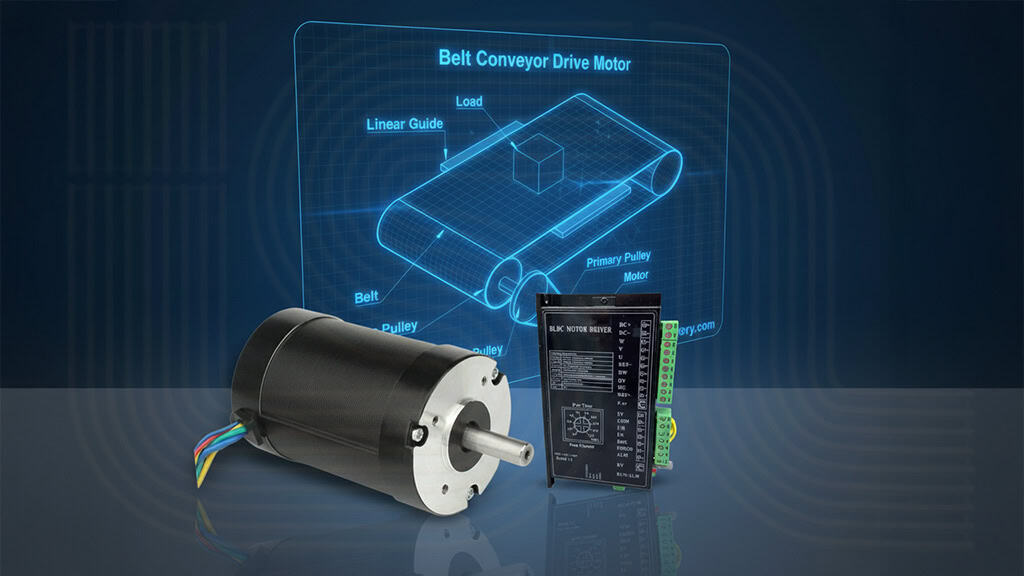

This report presents a technical case study evaluating the suitability of the BLDC-J57-87-36-4800-03 brushless DC motor, in conjunction with the MC-BLDC-300-S brushless motor driver, for application in a continuous-duty industrial conveyor belt system. The analysis, grounded in available technical specifications and a comprehensive comparative review, concludes that this BLDC system represents a superior and strategically advantageous solution. Key findings indicate that the system’s high efficiency, minimal maintenance requirements, and precise speed control directly address the most critical operational demands of modern industrial automation, including the need for continuous, trouble-free operation and lower Total Cost of Ownership (TCO). While the initial capital outlay may be higher than for traditional brushed DC or stepper motor solutions, the long-term benefits of enhanced reliability, reduced downtime, and lower energy consumption far outweigh this disparity, positioning the BLDC solution as a future-proof investment for Industry 4.0 environments.

The primary objective of this report is to provide a comprehensive, expert-level technical analysis of the BLDC-J57-87-36-4800-03 brushless motor and its associated MC-BLDC-300-S brushless motor driver. The report aims to serve as a definitive resource for industrial engineers and systems integrators, going beyond a simple datasheet summary to provide a nuanced understanding of the system’s performance, strategic advantages, and long-term viability. The analysis proceeds by constructing a conceptual profile of the motor based on the confirmed specifications of its companion driver, the MC-BLDC-300-S ¹, and by leveraging established engineering principles and comparative data from other motor technologies. This approach ensures the case study is grounded in logical inference and broad industry knowledge, particularly in the absence of a detailed datasheet for the BLDC-J57-87-36-4800-03 motor.

Conveyor belts are the central nervous system of materials handling in a wide array of industries, including manufacturing, logistics, and packaging.² They are the fundamental link in the production and distribution chain, responsible for transporting goods, raw materials, and finished products between different workstations. The demands on these systems have evolved significantly, moving from traditional, low-tech solutions to high-throughput, interconnected production lines. This transition places new and critical demands on the motor technology that powers them. Modern conveyor systems require not just raw power but also high energy efficiency, precise and repeatable speed control, and robust reliability to minimize unscheduled downtime. The shift towards greater automation and the principles of Industry 4.0 has rendered traditional electromechanical components, such as brushed DC motors, increasingly less viable due to their inherent limitations. This industry-wide evolution sets the stage for the need to explore more advanced and durable solutions, such as the BLDC system analyzed in this report.

Industrial conveyor systems are often a part of a larger production line that operates continuously for multiple shifts, making them a continuous-duty application.⁵ This necessitates a motor designed for “long, trouble-free continuous duty operation”.⁵ This requirement stands in direct contrast with traditional brushed motors, which are often recommended for “intermittent duty operation” due to the wear and tear on their brushes and commutators.⁶

A conveyor motor must consistently handle “varying loads” ³ and maintain a “constant torque, regardless of load and speed” ³ to ensure a consistent flow of products. The ability to provide precise and variable speed control is also a critical requirement for synchronizing with other operations on the production line, such as inspection, labeling, or packaging.⁸ Given that conveyor systems often run 24/7, energy consumption is a major operational cost. Therefore, a primary driver for motor technology selection is the need for a solution that offers “higher efficiency, leading to lower energy consumption and reduced heat generation”.⁹

The industrial environment can be harsh, with exposure to dust, debris, and temperature fluctuations. From a maintenance perspective, unscheduled downtime is one of the most significant costs in industrial automation. A motor that requires “minimal maintenance” ⁹ due to the absence of wear-prone components is a major operational advantage. While brushed motors require regular inspection and replacement of brushes or the motor itself ⁶, the longevity of the electronic controller and contactless commutation in a brushless system far surpasses the limited lifespan of the wear components in a brushed motor.⁶ The reduction in maintenance labor and part replacement costs, combined with the avoidance of costly production stoppages, makes a low-maintenance motor a key strategic asset.

The MC-BLDC-300-S is a high-performance brushless DC motor controller designed for efficient and precise motor control.¹ It serves as the intelligent core of the system, managing the motor’s operation and safeguarding it against common industrial faults. The driver operates at a nominal 48VDC with a broad supply voltage range of 18V to 50VDC.¹ It can deliver up to 15A of output current and a maximum of 300W of power, a key metric that defines the system’s capacity for light to moderate loads.¹

The controller’s sophistication is evident in its advanced functionalities, which include start/stop control, speed regulation, forward/reverse operation, and communication capabilities.¹ The presence of these features makes the system ideal for integration into a sophisticated, networked automation line. Furthermore, the driver’s compatibility with 3-phase BLDC motors and its use of Trapezoidal commutation via Hall Effect Sensors ¹ are features that dictate the architecture of the paired motor and explain the mechanism for the system’s “smooth and efficient rotor rotation”.¹¹ The Hall effect sensors enable a form of closed-loop control, which is crucial for a conveyor belt application. This allows the driver to constantly monitor the rotor’s position and adjust the current to the windings, ensuring consistent performance even with fluctuating loads.⁴ Lastly, the built-in over-voltage and over-current protection features are vital for safeguarding the system against common industrial faults, preventing costly damage and enhancing overall reliability.¹

Table 3.1: MC-BLDC-300-S Motor Driver Key Specifications

| Specification | Value |

| Nominal Voltage | 48VDC |

| Voltage Supply Range | 18V to 50VDC |

| Max Output Power | 300W |

| Max Output Current | 15A |

| Commutation Type | Trapezoidal |

| Sensor Compatibility | Hall Effect Sensors |

| Control Features | Start/Stop, Speed Regulation, Forward/Reverse, Communication Capabilities |

| Protection Features | Over-voltage, Over-current |

| Mounting Type | Chassis-mount |

Based on the capabilities of the MC-BLDC-300-S driver, the BLDC-J57-87-36-4800-03 motor is designed to operate within the driver’s power envelope, with an output of up to 300W. The motor’s designed to operate at a nominal 36VDC voltage which is compatible with the driver’s voltage range of 18V to 50VDC.

A motor with a no-load speed of 4,800 RPM is fundamentally designed for high-speed, low-torque operation. However, conveyor belt applications require a different performance profile, namely high torque at relatively low speeds to move heavy loads with control.² This apparent conflict is resolved by the fundamental engineering principle of a gearmotor or external pulleys and belts. Planetary gearmotors are explicitly noted as the “best motors for automated conveyor belts” and are known for their ability to provide “high torque capacity” and “high gear ratios” in a compact form factor.¹² For the BLDC-J57-87-36-4800-03 motor to be functionally suitable for this application, it must be paired with an appropriate planetary gearhead or external pulley. The gearhead or pulley converts the motor’s high speed and low torque into the high torque and low speed required for a conveyor belt application. Therefore, the most pragmatic evaluation is of the complete system—the BLDC motor paired with an appropriate gearbox or pulley—which represents a complete and viable solution for industrial automation.

The core design of a brushless DC motor—without brushes or commutators—eliminates friction losses and electrical arcing, leading to higher efficiency and reduced heat generation compared to brushed motors.⁶ The use of powerful permanent magnets also results in a higher torque-to-weight ratio, which allows for a smaller, more compact design.⁹

The elimination of wear-prone components like brushes is arguably the single most compelling argument for BLDC technology in a continuous-duty industrial setting.⁹ This design translates directly to a “longer lifespan” and “lower maintenance requirements” ⁹, drastically reducing both part replacement costs and, more critically, downtime. The system’s precision is a direct result of its electronic, closed-loop commutation. Fluctuating loads, such as adding more items to a conveyor, can cause a motor’s speed to drop. The MC-BLDC-300-S driver, through the use of Hall effect sensors, receives continuous position feedback.¹ This feedback allows the driver to “constantly monitor and adjust the motor speed and torque” ⁴, ensuring a “consistent performance even with load fluctuations”.⁴ This stable speed control is a core requirement for reliable conveyor operation.

Furthermore, the smooth operation of a BLDC motor extends beyond just lower acoustic noise. The absence of electrical arcing from brushes eliminates significant electrical noise.¹¹ This is a critical factor in a modern industrial automation line, which is a highly integrated environment relying on sensitive electronic control systems like Programmable Logic Controllers (PLCs). The electrical noise generated by brushed motors can interfere with these sensitive circuits. The reduced electromagnetic interference (EMI) of the BLDC system thus contributes to a more reliable and robust overall automation line, ensuring data integrity and system stability.

When compared to other motor types, the BLDC system offers clear advantages.

Table 4.2: Comparative Motor Technology Analysis for Industrial Conveyors

| Metric | Brushless DC (BLDC) | Brushed DC | Stepper Motor |

| Efficiency | High ⁶ | Lower due to friction ⁹ | Lower due to continuous current draw ¹⁶ |

| Lifespan | Long ¹¹ | Shorter, limited by brushes/commutator ¹¹ | Long ⁸ |

| Speed Control | Precise, closed-loop with driver ⁴ | Simple, by varying voltage via PWM. ⁶ | Precise, stepwise motion ¹⁵ |

| Best-Fit Application | Continuous-run conveyors, variable speed ⁴ | Simple, constant-torque applications ¹⁶ | Precision positioning, indexing ¹⁵ |

| Initial Cost | Higher ¹¹ | Lower ¹¹ | Mid ¹⁶ |

| TCO | Low (due to efficiency/maintenance) | Lowest (due to simplicity of integration) | Low (due to inefficiency) |

While the initial cost of a BLDC system is higher due to the need for a sophisticated controller ¹¹, this capital outlay is more than offset by significant long-term savings. The “higher efficiency” ⁹ of the BLDC system, especially in a continuous-duty application, leads to substantial savings in electricity consumption over the system’s lifespan. These energy savings, compounded over years of 24/7 operation, represent a critical reduction in operational costs.

More significantly, the minimal maintenance requirements of the BLDC motor ⁶ eliminate the costs associated with parts (brushes, commutators) and maintenance labor. More critically, it prevents unscheduled downtime. In industrial automation, the cost of a production line stoppage can be astronomical, encompassing lost production, missed deadlines, and labor costs for troubleshooting and repair. The BLDC system’s inherent reliability and minimal chance of catastrophic failure from brush wear translate directly into a lower Total Cost of Ownership, making it a more economical choice over its operational life.

The BLDC solution is not merely a motor choice but a strategic investment for companies embracing automation and Industry 4.0. The system’s robustness, reliability, and high-tech control capabilities make it a key enabler for more efficient, predictable, and scalable production lines. Its ability to provide consistent performance under variable loads and its seamless integration into networked control systems align perfectly with the principles of modern manufacturing. Choosing this technology is a forward-thinking decision that enhances operational resilience and lays the groundwork for future system upgrades and optimization.

Based on a thorough technical analysis and comparative evaluation, the BLDC-J57-87-36-4800-03 motor, when paired with the MC-BLDC-300-S driver, is not merely a suitable choice but a superior choice for continuous-duty industrial conveyor belt applications. The system’s core technical merits—including its high efficiency, minimal maintenance, extended lifespan, and precise speed control under fluctuating loads—directly address the most critical pain points of industrial automation.

The BLDC system’s advantages far outweigh the higher initial cost when the analysis shifts to a long-term perspective. The significant reductions in energy consumption, maintenance costs, and, most importantly, unscheduled downtime, lead to a demonstrably lower Total Cost of Ownership. It is recommended that this powerful BLDC motor be integrated with a planetary gearhead to achieve the optimal speed-torque profile required for the application, ensuring maximum efficiency and reliability for modern industrial operations.