Submit Your Request

Please fill out the form below.

Please fill out the form below.

Need a custom solution?

Computer Numerical Control (CNC) is a cornerstone of modern manufacturing, a domain where high-precision, repeatable, and robust motion control is paramount. CNC machines rely on a sophisticated array of motors to manage primary linear axes (X, Y, Z) for cutting and shaping, as well as for ancillary functions like automated tool changers (ATCs) and workpiece clamping mechanisms. The motors chosen for these applications must deliver not only power but also positional accuracy, repeatability, and holding torque. For decades, the choice has often been between high-precision, expensive servo systems or more affordable, open-loop stepper motors.

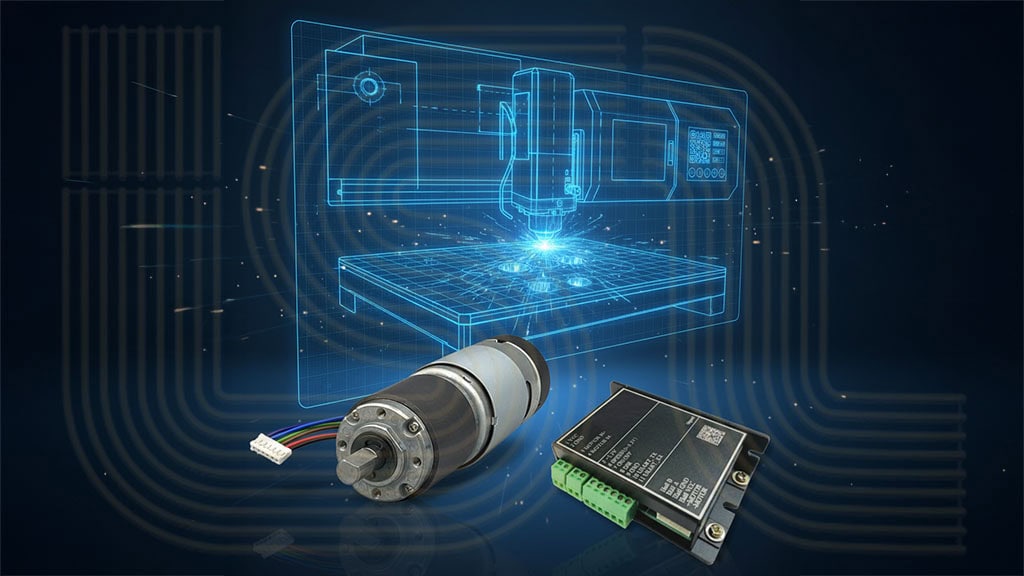

This comprehensive case study covers a unique electromechanical gear motor: the ISL PGM-38P-24-51-125-02E brushed planetary gear motor paired with the MC-BDC-S brushed DC motor controller. At first glance, a brushed DC motor may seem like a low-tech solution for a modern CNC machine. However, the MC-BDC-S driver, which enables closed-loop control via encoder feedback, fundamentally transforms the motor’s capabilities. This combination allows the system to operate as a functional servo, offering a compelling alternative to traditional motor technologies for specific, targeted applications within the industrial automation landscape. This analysis will not only detail the technical specifications of these components but will also analyze their practical application, evaluate their performance against industry standards, and provide a strategic assessment of their long-term value within a precision manufacturing environment.

The PGM-38P-24-51-125-02E is a planetary gear motor designed to provide excellent torque output within a compact, inline form factor. As the detailed specification notes, it is a carbon-brushed DC gear motor with a rated voltage of 12V DC. The integrated planetary gearhead has a reduction ratio of 51:1, translating a high motor speed into a usable output speed and significantly boosting torque. The motor’s rated speed is 103 rpm at a rated torque of 15 kg.cm.

The motor’s performance curve shown in the datasheet further details the relationship between speed, torque, and efficiency, providing a clear map of its operational characteristics. The PGM-38P-24-51-125-02E is best suited for intermittent duty operation—best for applications with start-stop cycles rather than continuous running.

The MC-BDC-S is a high-performance brushed DC motor controller designed to manage a single brushed motor. It operates on a broad supply voltage range of 10V DC to 30V DC and is capable of providing up to 5A of output current, with a maximum power output of 100W. Its functionality is what elevates the PGM-38P-24-51-125-02E from a simple motor to a precision motion control component.

The driver offers several advanced functions critical for automation, including variable speed control, directional control (forward/reverse), and data transmission capabilities via USART. Most importantly, it is designed for closed-loop feedback control and is compatible with brushed DC servo motors equipped with a magnetic encoder. This closed-loop capability is essential for any CNC application that requires accurate and repeatable positioning.

Given its viability in CNC machine sub-systems, the combination of the PGM-38P-24-51-125-02E gear motor and MC-BDC-S motor controller is best suited for auxiliary sub-systems within a CNC machine. A particularly well-suited application is the electromechanical actuation of an Automated Tool Clamping and Un-clamping mechanism.

The ATC clamping mechanism is a common feature on modern CNC routers and milling machines, responsible for securely holding a tool in the spindle during cutting and releasing it for a tool change. This operation is a perfect match for the PGM-38P-24-51-125-02E system for several key reasons:

In this application, the PGM-38P-24-51-125-02E system’s operation is straightforward. The CNC machine’s main controller sends a command to the MC-BDC-S driver to initiate a tool clamp or un-clamp cycle. The driver, leveraging its onboard control functions, uses an internal PID loop and feedback from an encoder to drive the motor to a precise angular position. The motor’s planetary gearhead provides the necessary torque to actuate the clamping mechanism. Since the clamping action is brief and does not require high speed or continuous power, the system’s current draw remains well within the MC-BDC-S’s 5A limit, thereby preventing the over-current protection from engaging.

The PGM-38P-24-51-125-02E system’s combination of high torque, compact size, and closed-loop control provides a robust, reliable, and cost-effective solution for a critical but intermittent CNC sub-system, a role for which it is uniquely suited.

A thorough evaluation of the PGM-38P-24-51-125-02E system requires a comparative analysis against other motor technologies commonly found in industrial automation. This comparison reveals the strategic trade-offs and value proposition of brushed DC technology in a modern context.

Stepper motors have long been the default choice for low-cost, precision positioning applications in CNC machines, 3D printers, and robotics. They operate in discrete steps, with the controller knowing the motor’s position by simply counting the steps. This open-loop nature, however, has a significant drawback: a stepper motor can “miss a step” if it encounters too much resistance or is subjected to an excessive load, leading to a loss of positional accuracy.

The PGM-38P-24-51-125-02E gear motor, when paired with an encoder and the MC-BDC-S driver, overcomes this limitation by operating in a closed-loop system. The encoder continuously reports the motor’s actual position, allowing the controller to correct for any positional errors in real-time. This provides a level of reliability and repeatability that is difficult to achieve with an open-loop stepper system. While steppers are excellent at maintaining a fixed position by consuming maximum current, they can be less efficient at higher speeds as their torque decreases. Brushed DC motors, in contrast, offer a more consistent torque curve across their operating range, making them better suited for continuous operation. Despite the higher initial cost of a closed-loop brushed DC system, its superior positional certainty can lead to greater long-term productivity and reliability.

Brushless DC motors represent a technological advancement over their brushed counterparts, offering superior performance in many metrics. The most significant difference is lifespan. Brushed motors rely on physical brushes and a commutator to switch current, components that wear down over time due to friction and electrical arcing. BLDC motors eliminate these components, using an electronic controller for commutation instead, which results in a significantly longer lifespan.

Furthermore, the absence of brushes and the associated friction means BLDC motors are inherently more efficient, often exceeding 85% efficiency compared to the 70-80% range of brushed motors. This translates directly to lower energy consumption and reduced heat generation. While the initial cost of a BLDC system is higher due to the need for a more sophisticated electronic drive, its higher efficiency and reduced maintenance can lead to a lower total cost of ownership (TCO) over its operational life. For applications requiring continuous operation, a BLDC motor is the clear choice. The intermittent duty cycle of the PGM-38P-24-51-125-02E within this CNC application helps to prolong its service life, making its TCO more competitive in a specific niche.

Traditional servo motors are the gold standard for high-performance motion control, offering exceptional torque density, responsiveness, and precise closed-loop control. The PGM-38P-24-51-125-02E gear motor, equipped with its magnetic encoder, effectively functions as a brushed DC servo motor. It demonstrates that a brushed DC motor can meet the demands of a servo application without the complexity or expense of a full-fledged servo system.

The primary trade-off is in control complexity and responsiveness. True servo systems are typically more powerful and offer superior dynamic response for highly demanding applications. However, they are also more expensive and require more complex tuning and programming. The PGM-38P-24-51-125-02E offers a more affordable and simpler entry point into closed-loop motion control. It can provide the necessary precision and torque for applications that do not require the exceptional speed and responsiveness of a high-end servo, providing an optimal balance of cost and performance.

| Attribute | PGM-38P-24-51-125-02E w/ MC-BDC-S | Stepper Motors | Brushless DC (BLDC) Motors | Servo Motors |

| Control | Closed-Loop | Open-Loop | Closed-Loop | Closed-Loop |

| Precision | Excellent (via encoder feedback) | Good (can miss steps) | Excellent | Excellent |

| Efficiency | Lower (70-80%) | Low | High (85-95%) | Highest |

| TCO | Low initial cost | Lowest initial cost; can be a poor TCO for demanding applications | Higher initial cost; lower TCO for long-term use | Highest initial cost; lowest TCO for high-demand applications |

| Best-Fit Apps | Intermittent, high-torque sub-systems | Low-speed, low-cost positioning | Continuous-duty, high-efficiency | High-speed, high-precision, dynamic control |

The PGM-38P-24-51-125-02E is a great solution for a variety of sub-systems within CNC machines. When paired with the MC-BDC-S brushed dc motor controller, they offer an exceptionally cost-effective and precise motion control system.

The pairing of the PGM-38P-24-51-125-02E gear motor with the MC-BDC-S controller offers a unique balance of cost, torque, and closed-loop control, making it a compelling solution for specific, intermittent-duty, high-torque sub-systems within a CNC machine. The optimal application is one that does not require continuous, high-speed operation for prolonged operating life. Examples include:

For engineers and system designers considering the PGM-38P-24-51-125-02E, several recommendations are paramount for successful implementation and long-term reliability:

The ISL PGM-38P-24-51-125-02E gear motor in conjunction with the MC-BDC-S driver is a highly viable and cost-effective closed-loop motion solution. While modern industrial trends favor the efficiency and longevity of brushless and servo technologies, the PGM-38P-24-51-125-02E showcases that brushed DC motors still hold a valuable and enduring place in the market. Its unique balance of high torque, compact design, and competitive initial cost, when paired with an intelligent controller, makes it an optimal choice for the right niche applications. For system integrators who can accurately assess their functional requirements, the PGM-38P-24-51-125-02E offers a robust and reliable solution that provides a powerful blend of performance and economic value in the field of industrial automation.