Submit Your Request

Please fill out the form below.

Please fill out the form below.

Need a custom solution?

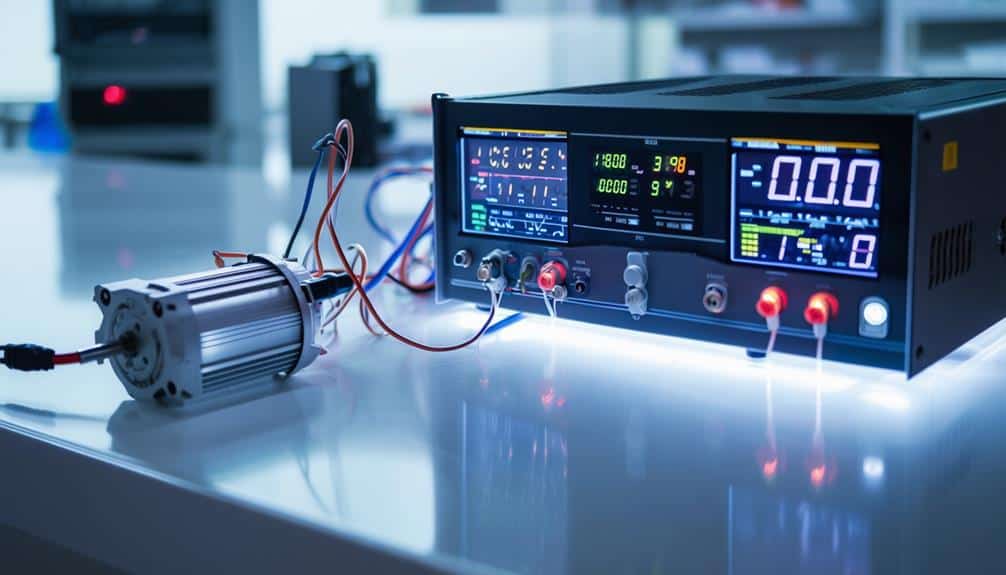

Discover the dynamic domain of maintaining DC motors and troubleshooting typical tribulations.

From frayed wires to worn-out brushes, the realm of motor management is multifaceted.

Uncover practical pointers for prolonging motor prowess and resolving pesky problems.

Stay tuned to unravel the secrets of keeping your DC motors running smoothly and efficiently.

Regular maintenance of DC motors is crucial for ensuring optimal performance and longevity. By adhering to a consistent maintenance schedule, you can reap numerous benefits that far outweigh the costs involved.

One of the primary advantages of regular maintenance is the cost savings it offers. Through proactive upkeep, you can identify and address potential issues before they escalate into major problems, saving you from costly repairs or replacements down the line. Additionally, well-maintained DC motors operate more efficiently, leading to energy savings and improved overall performance.

Furthermore, proper maintenance helps extend the lifespan of your DC motors, reducing the frequency of replacements and enhancing the reliability of your equipment. By investing in routine maintenance tasks such as cleaning, lubrication, and inspections, you can significantly prolong the operational life of your motors.

Ultimately, the benefits of maintenance go beyond just cost savings, as they also contribute to increased productivity, reduced downtime, and a more sustainable operation.

To maintain optimal performance of your DC motor, it’s essential to be aware of common issues that may arise during its operation. Here are some key points to consider:

Being vigilant about these common issues and addressing them promptly can help maintain the efficiency and longevity of your DC motor.

Performing scheduled maintenance tasks is crucial for ensuring the reliability and longevity of your DC motor. Two essential maintenance tasks to prioritize are motor cleaning and lubrication techniques. When it comes to motor cleaning, it’s vital to regularly remove any dirt, dust, or debris that may accumulate on the motor’s surface. Use a soft brush or cloth to gently clean the exterior of the motor, being careful not to damage any sensitive components. Additionally, inspect the ventilation openings and ensure they’re free from any obstructions to prevent overheating.

Lubrication techniques play a significant role in maintaining the efficiency of your DC motor. Make sure to follow the manufacturer’s guidelines on the type and amount of lubricant to use. Apply the lubricant to the specified parts at recommended intervals to reduce friction and wear, thus prolonging the motor’s lifespan. Proper lubrication also helps in minimizing noise and vibrations during operation. By performing these maintenance tasks diligently, you can keep your DC motor operating smoothly and prevent potential issues down the line.

For effective troubleshooting of DC motors, begin by systematically inspecting the motor’s components and connections for any signs of malfunction. To aid in fault diagnosis and repair, consider the following techniques:

Implement regular maintenance schedules to extend the lifespan of DC motors and prevent unexpected breakdowns. By following preventive measures, you can ensure the long-term efficiency of your equipment. Regularly inspecting and servicing DC motors can help identify issues before they escalate, saving time and money in the long run. Here are some preventive measures and long-term solutions to consider:

| Preventive Measures | Long-Term Solutions |

|---|---|

| Lubricate moving parts | Implement automated lubrication systems |

| Check for loose connections | Use locking mechanisms for connectors |

| Monitor temperature regularly | Install cooling systems for overheating prevention |

| Clean motor surfaces | Utilize protective coatings for increased durability |

You can’t run DC motors continuously without maintenance. While some may claim maintenance-free operation, all motors require periodic checks and care to ensure optimal performance and longevity. Regular maintenance is crucial for reliability.

When dealing with DC motors, less common issues like overheating problems and commutator issues can arise. These issues require immediate attention to prevent damage and ensure optimal motor performance. Regular maintenance can help identify and address these problems effectively.

You should inspect DC motors regularly to ensure optimal performance and longevity. Checking them at least once every six months is advisable for continued efficient operation over the long term.

When troubleshooting DC motor issues, you’ll need specific tools for diagnostics and equipment for testing. Utilize multimeters, clamp meters, insulation resistance testers, and oscilloscopes to identify and resolve potential problems effectively.

To ensure optimal performance and longevity of your DC motors, a recommended schedule for implementing preventive measures involves regular maintenance at specific intervals. This consistent approach to upkeep will help prevent issues and prolong continuous operation.

In conclusion, regular maintenance of DC motors is crucial to ensure optimal performance and longevity. By addressing common issues promptly and conducting essential maintenance tasks, you can prevent costly downtime and breakdowns.

Utilizing troubleshooting techniques will help identify and resolve any issues efficiently. Implementing preventive measures will further extend the lifespan of your DC motors. Stay proactive in maintaining your equipment to maximize efficiency and minimize disruptions in your operations.