Submit Your Request

Please fill out the form below.

Please fill out the form below.

Need a custom solution?

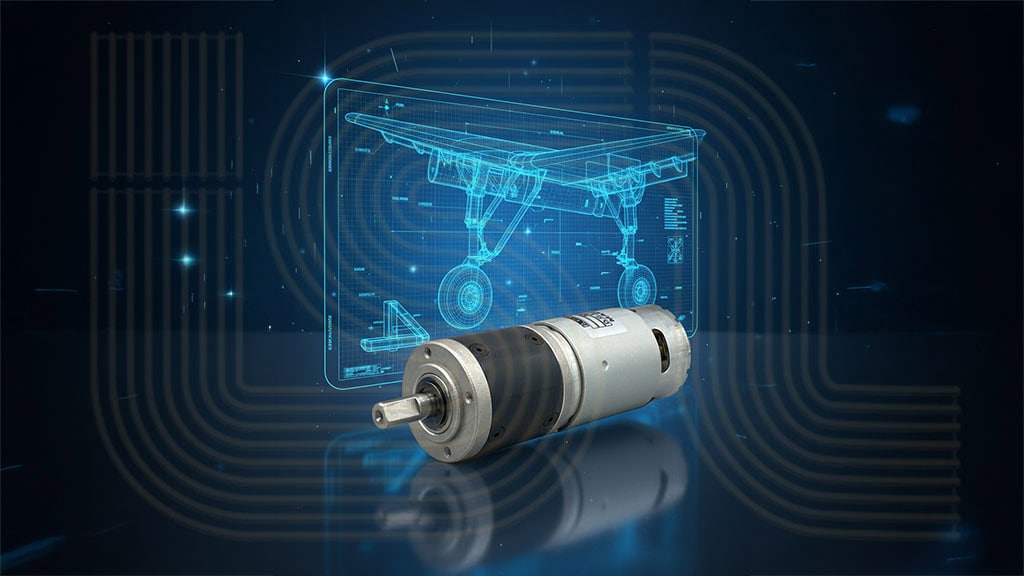

Designing components for personal aircraft demands an uncompromising blend of precision, reliability, and compact integration. Engineers in the aerospace sector frequently encounter the complex challenge of developing linear actuators that can perform critical functions, such as deploying and retracting landing gear, within extremely confined spaces. These actuators must deliver precise, controlled motion, handle significant and varying loads, and ensure unwavering reliability under intermittent, yet high-stress, operational cycles.

Consider a scenario where an aerospace manufacturer was developing a new personal aircraft, requiring a highly efficient and robust linear actuator system for its landing gear. The primary hurdle was the severe spatial limitation within the aircraft’s wing or fuselage, which dictated an exceptionally compact motor solution. Beyond size, the motor needed to provide substantial starting torque to initiate movement, manage the dynamic loads encountered during takeoff and landing, and ensure smooth, precise extension and retraction of the landing gear without stalling. Cost-effectiveness was also a key consideration, as traditional motor solutions were often too bulky, lacked the necessary torque-to-size ratio for the demanding application, or were too expensive for the project’s budget. Achieving this critical balance of performance, size, and economic viability was paramount for the safety and efficiency of the aircraft.

In response to these stringent aerospace requirements, ISL Products International identified the PGM-38P-12-51-392-CBB (MOT-I-81508-38-51) as the optimal solution. This high-quality Ø38mm Brushed Planetary Gear Motor was precisely engineered to address the customer’s multifaceted challenges, offering a blend of compact design, robust performance, and economic viability perfectly suited for critical linear actuation.

The selection of the PGM-38P-12-51-392-CBB was predicated on several key attributes that directly corresponded to the linear actuator’s critical needs:

The strategic integration of the PGM-38P-12-51-392-CBB into the customer’s linear actuator system yielded significant positive outcomes, directly addressing the initial challenges and surpassing performance expectations for personal aircraft landing gear.

The PGM-38P-12-51-392-CBB proved transformative for the aircraft’s linear actuator system. It successfully met the stringent requirements for precise speed control and delivered robust torque, even under dynamic and varying load conditions during landing gear operation. The motor’s inherent ability to provide high starting torque and maintain performance without stalling enabled seamless and highly accurate extension and retraction. This directly translated into improved operational efficiency and safety for the aircraft, ensuring that the landing gear could be deployed and stowed with consistent accuracy and optimal speed, thereby enhancing overall flight performance and reliability.

The motor’s compact size, with its Ø38mm diameter and 115.5mm overall length, was a pivotal factor in enabling a highly elegant and efficient mechanical design for the linear actuator system. This allowed the customer to successfully maintain the desired small footprint for their landing gear unit, which was a critical design objective for integration into the aircraft’s structure. The compact design not only minimized the overall system size but also contributed to reduced weight and increased flexibility in aircraft design.

The PGM-38P-12-51-392-CBB, leveraging its brushed DC motor technology, offered a remarkably inexpensive startup cost, which significantly contributed to meeting the project’s financial objectives. In a sophisticated B2B context, the understanding of “cost-effectiveness” extends beyond the initial purchase price to encompass the Total Cost of Ownership (TCO) relative to the achieved performance and, crucially, the suitability for the specific application over its operational lifespan. For this particular intermittent duty application, the PGM-38P-12-51-392-CBB offered a compelling and genuinely cost-effective TCO. The lower upfront cost directly addressed immediate budget constraints. Critically, the “intermittent duty” design mitigates the typical concerns regarding “shorter lifespan” and “higher maintenance” associated with brushed motors because the motor is not subjected to continuous, high-stress operation. This means the customer received the required high performance and precision at an optimal price point for their specific use case, without incurring unexpected failures or excessive, unscheduled maintenance. This nuanced understanding of value positions ISL as a strategic partner who not only supplies components but also deeply understands the economic realities and operational demands of their customers’ applications.

The high-quality construction inherent in the PGM-38P-12-51-392-CBB, coupled with its appropriate selection for the intended intermittent duty operation, ensured consistent and efficient performance throughout the linear actuator system’s operational lifecycle. This strategic pairing significantly minimized the risk of unexpected downtime and reduced unscheduled maintenance needs within the expected operational parameters. This predictability contributes positively to the motor’s overall longevity and ensures reliable performance in critical aircraft systems.

The PGM-38P-12-51-392-CBB proved to be an unequivocally ideal solution for this demanding linear actuation application in personal aircraft. Its successful integration stands as a testament to ISL Products International’s unwavering commitment to providing high-quality, versatile, and exceptionally reliable motor components that truly power innovation across various industries. The motor’s unique combination of compact size, robust torque delivery (meticulously optimized for handling momentary peaks), a high-precision planetary gearhead, and inherent cost-effectiveness made it the perfect fit for a scenario that rigorously demanded superior performance within exceptionally tight design and budget constraints.

The success of this specific solution naturally reflects positively on ISL Products International as a whole. This outcome elevates ISL Products International beyond merely being a component supplier. By emphasizing ISL’s commitment to providing high-quality, versatile, and reliable motor components and extending an invitation for customers to discuss their specific requirements, the messaging pivots to position ISL as a comprehensive solutions provider and a trusted technical partner. This fosters a perception of expertise and reliability that extends across their entire product range. This strategic framing of the call to action is crucial for long-term business development, transforming the positive outcome of a single case study into a powerful endorsement for ISL’s broader capabilities and customer-centric approach. This not only encourages inquiries for other products but also strengthens brand reputation, fosters customer loyalty, and ultimately enhances ISL’s market position as a leader in motor solutions.

We invite you to discover how ISL Products International’s extensive range of Brushed Planetary Gear Motors, alongside our diverse portfolio of other motor solutions, can significantly benefit and elevate your next groundbreaking project. Our team of highly experienced experts is readily available to assist you in meticulously selecting the optimal component engineered precisely for your specific requirements. Contact us today to discuss your vision and let ISL Products be the driving force that powers your innovation.

Its compact Ø38mm diameter and 115.5mm overall length are crucial for space-constrained designs within aircraft. This is combined with its high torque output and a precision planetary gearhead, allowing for powerful and accurate linear motion, essential for critical functions like landing gear deployment.

The gear motor itself can theoretically reach a high stall torque of 185 kg.cm. However, the integrated planetary gearbox has a continuous operational limit of 75 kg.cm to ensure its longevity and to prevent damage to the internal gearing. Importantly, the gearmotor assembly can handle significant momentary peaks up to approximately 100 kg.cm, which is ideal for high starting loads and transient demands in applications like linear actuators.

The PGM-38P-12-51-392-CBB is explicitly best suited for intermittent duty operation. This design choice optimizes its lifespan and performance for applications characterized by start-stop cycles and periods of rest, such as the periodic deployment and retraction of aircraft landing gear.

Key advantages include its inherent high starting torque, straightforward and cost-effective speed control achieved simply by utilizing a PWM (Pulse Width Modulation) controller, and a lower initial acquisition cost compared to more complex brushless motor alternatives.

Brushed DC motors generally have an operational lifespan ranging from 300 to 500 hours. This lifespan is optimized for applications designed for intermittent duty, where the motor is not continuously running at peak loads, which aligns well with linear actuator cycles in aircraft.

The planetary gearhead is crucial for precision. It provides excellent torque multiplication and high efficiency, features a compact design, and is known for its high precision. Additionally, it significantly reduces vibrations and noise, leading to much smoother and more accurate operation, which is vital for precise positioning tasks in linear actuators.

Speed control for brushed DC motors is remarkably simple and cost-effective. The motor’s rotational speed is directly proportional to the applied input voltage, allowing for easy and precise speed adjustments by utilizing PWM control. We suggest utilizing our PWM motor speed controller: MC-BDC-PWM-S (MOT-DRV PWM).

In addition to linear actuators for personal aircraft landing gear, this versatile motor is highly suitable for a wide array of applications including other types of linear actuators, industrial automation systems, robotics, certain medical devices, and other specialized machinery where a compact size, high torque, and intermittent duty cycle are key operational requirements.

ISL Products International is committed to high-quality construction and provides comprehensive, detailed specifications and expert application guidance. This ensures that customers select the most appropriate motor for their specific needs, leading to reliable and efficient performance and minimizing the risk of unexpected downtime, especially in critical applications like aircraft systems.